Due to the increasingly complex demands of today's architects and designers, the design and layout of anchors and splices in reinforced concrete involved a unique combination of art and science. Practical consideration limits full length continuous reinforcement throughout any sizable structure. Splicing of reinforcement becomes unavoidable.

Traditionally accepted forms of splicing reinforcing steel bars have been to lap them. The method involves placing two bars together next to each other, over defined minimum lengths and then holding them in position using wire ties.

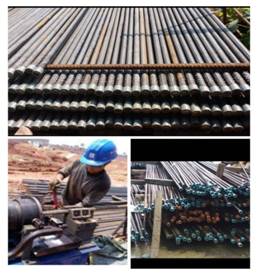

At Ravimax we have developed a mechanical splicing system. The system involves the use of couplers, that is cost effective, quick and easy to install and results in a superior splice. Importantly engineers globally have recognized the advantages of the splicing system overlap system.